In industrial production, valve packing seals are essential components that ensure equipment operates smoothly while preventing fluid leakage. However, these seals often face wear during operation, which can compromise sealing performance and even pose safety hazards. Lubrication plays a critical role in mitigating wear and extending service life. This article explores the wear mechanisms of valve packing seals, the importance of proper lubrication, and strategies for selecting and applying lubricants effectively.

Common Causes of Packing Seal Wear

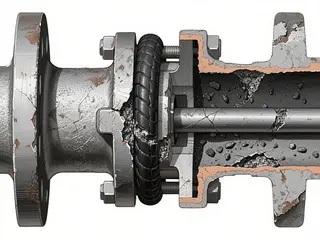

Valve packing seals prevent fluid leakage by maintaining tight contact with the valve stem or rotating shaft. However, friction during movement inevitably causes wear, affecting both the packing and the stem. Factors influencing wear include material properties, movement speed, lubrication, cooling, and the quality of packing installation.

- Packing Installation

Wear is typically greatest at the gland and decreases inward due to uneven radial contact stress. Improper installation—such as uneven layers or incorrect tightness—can create high-stress zones, accelerating wear and compromising sealing performance. - Non-uniform Movement

If the valve stem moves off-axis or lacks coaxiality with the packing box and rings, circumferential non-uniform wear occurs. This uneven contact increases localized pressure, accelerating deterioration. Ensuring proper stem alignment and correct packing installation is crucial for reducing wear.

The Role of Lubrication in Reducing Wear

Lubrication is a key method for minimizing friction, dissipating heat, and preventing damage to packing seals. Selecting the right lubricant and applying it correctly directly impacts the seal’s longevity and effectiveness.

- Types of Lubricants

Common lubricants include oils, greases, and solid lubricants. Many braided packings are pre-impregnated with self-lubricating or high-temperature-resistant materials. In high-pressure, high-speed, or high-temperature conditions, forced lubrication and cooling are often required. - Functions of Lubricants

Lubricants form a film between the packing and valve stem, reducing direct contact and wear. They also carry away friction-generated heat. In high-temperature applications, using heat-resistant lubricants is essential to prevent evaporation and dry friction, which can damage the packing. - Selecting the Right Lubricant

Lubricant choice depends on operating conditions:

- Speed of Movement: High-speed applications require lubricants with good penetration and moderate viscosity; low-speed, high-load conditions may require higher viscosity lubricants.

- Load or Pressure: Heavier loads demand lubricants with higher viscosity to maintain effective lubrication.

- Impact and Vibration: Intermittent or reciprocating motions need greases or solid lubricants with higher viscosity to maintain a stable lubricating film.

- Temperature: Select lubricants based on the working temperature of both the medium and sealing area; for temperatures exceeding 200°C, solid lubricants are preferred.

- Environmental Conditions: In humid or dusty environments, use water-resistant lubricants and ensure packing boxes are well-sealed to prevent contamination. In corrosive atmospheres, anti-corrosive lubricants provide additional protection.

Optimizing Lubrication Systems

Beyond choosing the right lubricant, designing an effective lubrication system is crucial. A follower ring in the packing assembly can serve as both a lubrication port and a leakage monitoring channel.

- Lubricant Injection

Forced lubrication systems can deliver lubricant consistently, preventing dry friction and heat buildup, especially in demanding conditions. - Leakage Monitoring

Installing a follower ring allows real-time leakage monitoring. When excessive leakage is detected, sealing compounds can be applied promptly, reducing downtime and improving operational efficiency.

Practical Application Example

In a chemical plant, a high-temperature, high-pressure valve experienced rapid packing wear. The root cause was the evaporation of heat-sensitive lubricating oil, leading to dry friction. By switching to a high-temperature solid lubricant and implementing forced lubrication, the service life of the packing increased significantly, and leakage was effectively controlled.

Conclusion

Packing seal wear directly impacts sealing performance and equipment safety. Effective lubrication—through careful selection of type, viscosity, heat resistance, and environmental suitability—combined with optimized lubrication systems, can significantly reduce wear and extend service life. Additionally, real-time leakage monitoring and timely remedial measures ensure continued sealing performance. Understanding these principles enables improved efficiency, safety, and reliability in industrial operations.It’s important to know about Google SEO to help your website rank higher in search results.