The modern electronics production has been adopted as contract electronic manufacturers (CEM). These niche firms can design and assemble finished products, overseeing all aspects of the design process to the last stage, which gives a company an opportunity to introduce electronic products to the market without having to develop large in-house production facilities.

Start-up working on your first IoT device or an established company planning to scale the production, knowing what CEMs can provide may help to make better decisions related to the manufacturing strategy. Let us take a look at the essence of the services that make such partnerships so valuable.

Design and Engineering Services

Majority of contract electronic manufacturers do not just assemble. They also provide you with full design and engineering assistance that can make your idea a product that can be manufactured.

Design for Manufacturing (DFM) consultation helps in designing your product to attain efficient production. Engineers look through your specifications and propose changes that will save on costs, enhance reliability, and also facilitate the process of assembly. Such early development can frequently avoid expensive redesigns towards the end of the development cycle.

Prototyping can aid you to test and enhance your design before investing in commercial manufacturing. Several CEMs are able to sustain a rapid prototyping process with working samples within days or weeks instead of months.

Another service that is critical is component sourcing and selection. CEMs use supplier relations and the learning about the market to suggest the cheap parts and still guarantee availability and compatibility with your design needs.

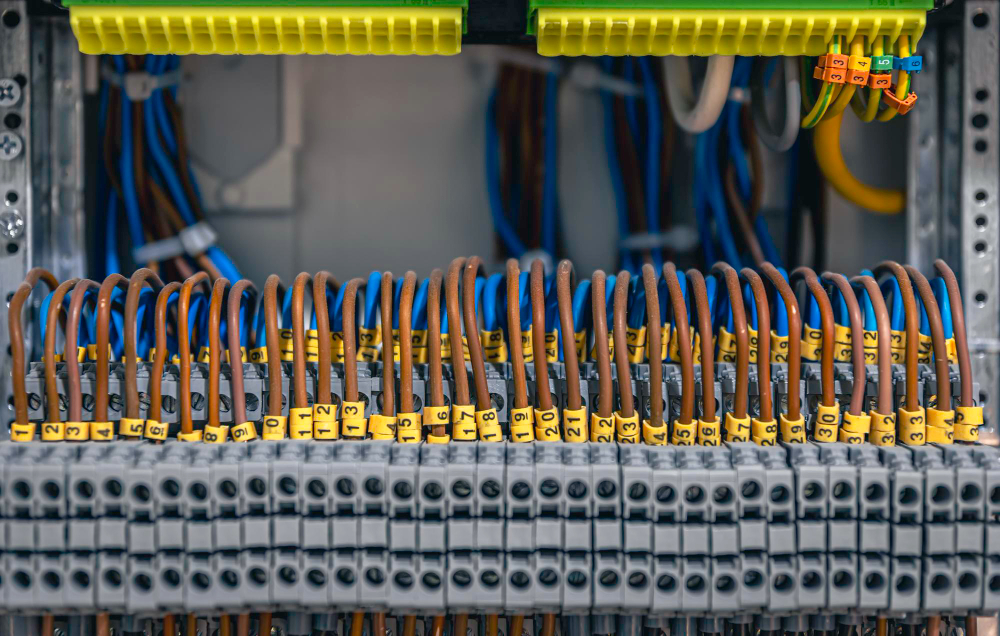

Printed Circuit Board Assembly and Manufacturing

Most of the CEP activities are centered around printed circuit board (PCB) assembly. This entails attaching electric devices to bare circuit boards with advanced automated machines.

Most of the modern electronic components are processed by Surface Mount Technology (SMT) assembly. Pick-and-place machines operate at high speed and the tiny elements are placed with remarkable accuracy and temporary solder links are established by the reflow ovens.

Through-hole assembly deals with the parts to be inserted by inserting them through holes in the board. It is not very frequent, but such a process is needed to connectors, large capacitors, and other special components.

Mixed-technology assembly is based on SMT and through-hole assembly on the same board, highly coordinated and needs special skills to achieve the right outcomes.

Testing and Quality Control

Quality electronics must have tough testing during the production process. CEMs usually provide different levels of testing to discover defects in time and to provide stability in the quality.

In-circuit testing (ICT) is employed to make certain that components are in line and soldered. Automated test equipment measures electrical continuity, element values and easy operation even while the remaining of the circuit is not energized.

Functional testing is a test that is conducted to determine whether the product assembled has come to specifications. This can be with custom test fixtures and software which mimics real world operating scenarios.

To test the reliability of a product over the long term, environmental testing is used to expose the products to temperature extremes, humidity, vibration, and other stresses. A large number of CEMs have environmental chambers and are able to perform accelerated aging tests.

Supply Chain Management

Handling the procurement of components and inventory is a huge value add on the part of most CEMs. They have established their relationships with suppliers and purchase quantities, which can translate into a lower price and increased availability.

Components can be on consignment to inventory management services and this saves your working capital, but production will not cease. Other CEMs have vendor-managed inventory programs whereby they predict and buy parts in accordance with your production schedules.

The management of obsolescence assists in the handling of end-of-life scenarios of components. Experienced CEMs are able to propose substitute parts or assist in acquiring last-time-buy levels to provide time gaps before redesigns are finished.

Final Assembly & Packing

A lot of CEMs do not just stop at PCB assembly and go the extra mile to finish the products.

PCBs are added in into enclosures, cables and connectors added, & the final product assembled in mechanical assembly. This might entail multistage procedures with numerous sub-assemblies.

Programming and calibration services program and setup the firmware, and may do any other required calibration. This is to make sure that every unit arrives as ready to use without the need to further set up.

Retail-ready packaging design and fulfillment can also be used in custom packaging, where the goods are shipped to distributors or end consumers.

Conclusion

Contract electronic manufacturers do not simply perform particular assembly work but provide complex services that are far much more than that. Starting with design support up to the final packaging, the appropriate CEM partner will dramatically speed up your time-to-market and make the manufacturing process simpler.

The key factors to succeeding with CEM partnerships are based on effective communication, set expectation, and selecting a manufacturer that can meet your unique needs. Before committing themselves, take time to analyze the technical capability of their potential partners, their quality systems, and their history in your industry.

Electronics manufacturing environment keeps changing fast. Having seasoned CEMs enables you to concentrate on your own competences and enjoy the benefits of specialized manufacturing know how to introduce better products to the market at a faster rate.