In the fast-paced world of food manufacturing, safety is not just a priority—it is a legal and ethical imperative. Among the various tools used to safeguard the food supply, the food metal detector stands as a critical line of defense. This article explores how these sophisticated systems operate, their role in regulatory compliance, and why they are indispensable for brand protection.

1. The Critical Need for Metal Detection

Despite rigorous safety protocols, physical contamination remains a persistent threat in food processing. Metal fragments can enter the production line through various channels:

- Machine Wear and Tear: Slicing blades, mincer plates, and worn-out conveyor parts.

- Raw Material Impurities: Staples, wires, or buckshot present in ingredients from the source.

- Maintenance Activity: Loose screws, washers, or clippings from repair work.

If these fragments reach the consumer, the consequences are severe: dental injuries, internal lacerations, and catastrophic damage to a brand’s reputation.

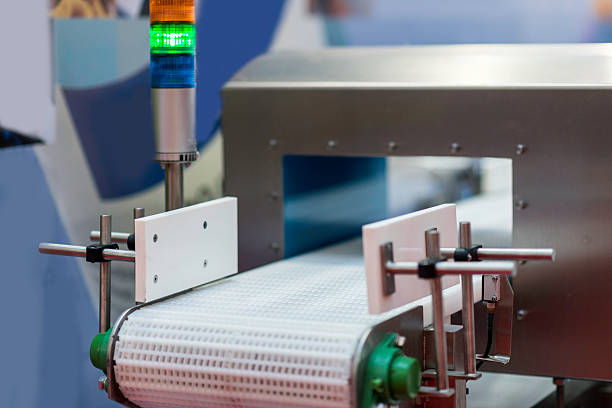

2. How Food Metal Detectors Work

Modern food metal detectors typically operate on the “Balanced Coil” principle. This system uses three separate coils wound around a non-metallic frame:

- A Center Transmitter Coil: Generates a high-frequency electromagnetic field.

- Two Outer Receiver Coils: Positioned on either side of the transmitter.

When the system is “balanced,” the two receiver coils detect identical signals, resulting in a net output of zero. However, when a metallic particle passes through the aperture, it disturbs the electromagnetic field. The detector senses this tiny change in voltage, triggering an alarm or an automatic rejection mechanism.

Different Metals, Different Challenges

Not all metals are detected with the same ease. Detectors categorize contaminants into three groups:

- Ferrous Metals (Iron, Steel): Magnetic and conductive, making them the easiest to detect.

- Non-Ferrous Metals (Copper, Aluminum): Non-magnetic but highly conductive; relatively easy to identify.

- Stainless Steel: The most challenging because it is often non-magnetic and a poor conductor. Specialized “multi-scan” or high-frequency detectors are required to find small stainless-steel fragments.

3. Ensuring Compliance: HACCP and GFSI Standards

In the food industry, compliance isn’t optional. Metal detectors are a foundational component of Hazard Analysis and Critical Control Points (HACCP).

The Role of CCPs

Under HACCP, a metal detector is often designated as a Critical Control Point (CCP). This means it is a specific stage where a hazard can be prevented, eliminated, or reduced to an acceptable level. To maintain compliance, manufacturers must:

- Establish Critical Limits: Define the minimum size of metal (e.g., $1.5text{mm}$ Ferrous, $2.0text{mm}$ Stainless Steel) the machine must detect.

- Monitor Regularly: Conduct “challenge tests” using certified test pieces (plastic sticks or cards containing a specific metal sphere) to ensure the machine is functioning.

- Maintain Records: Document every test, rejection, and corrective action for audit by bodies like the BRCGS (British Retail Consortium Global Standards) or IFS (International Featured Standards).

4. Strategic Placement in the Production Line

Where you place a metal detector is as important as the technology itself. Leading manufacturers use a multi-stage approach:

| Stage | Purpose | Benefit |

| Raw Material Intake | Inspects bulk ingredients. | Protects downstream machinery from damage. |

| In-Line / Pipeline | Inspects liquids, pastes, or powders. | Detects contaminants before they are broken into smaller pieces by mixers. |

| End-of-Line | Final check after packaging. | Provides the “final guarantee” before shipping to retailers. |

5. Overcoming “Product Effect”

One of the biggest hurdles in metal detection is Product Effect. Foods that are wet, salty, or hot (like fresh meat, cheese, or warm bread) are naturally conductive. This conductivity can mimic the signal of a metal contaminant, causing “false rejects.”

To combat this, advanced detectors use Simultaneous Multi-Frequency Technology. By scanning the product with multiple frequencies at once, the system can “ignore” the signal from the food and focus purely on the signal from the metal, significantly improving accuracy and reducing waste.

6. Beyond Safety: The Business Case

While safety is the primary driver, metal detectors offer significant economic benefits:

- Preventing Recalls: The cost of a single recall can reach millions of dollars in logistics, legal fees, and lost sales.

- Protecting Equipment: Catching a bolt before it hits a high-speed slicer prevents thousands of dollars in machinery repairs.

- Consumer Trust: In the age of social media, a single “metal in food” post can go viral. A robust detection program is the ultimate insurance policy for brand equity.

Conclusion

Food metal detectors are far more than just “magnets in a box.” They are highly engineered sensors that form the backbone of modern food safety systems. By integrating these systems into a comprehensive HACCP plan, food processors can ensure they meet global compliance standards while delivering a product that is safe for every dinner table.