Warehouse Services play a critical role in modern supply chains by providing businesses with a structured way to store, manage, and move goods efficiently. At a basic level, warehouse services involve receiving products from manufacturers or sellers, storing them safely, and dispatching them when required. Over time, warehousing has evolved from simple storage facilities into operational hubs that support inventory control, order fulfillment, and distribution planning across multiple channels.

Core Functions of a Warehouse Service

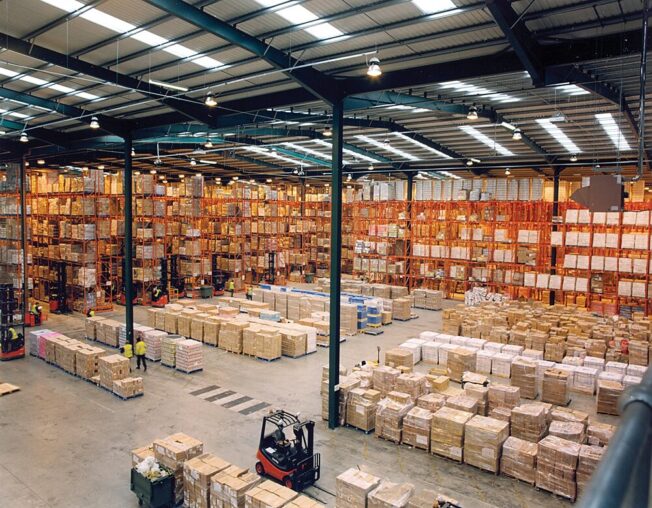

A standard warehouse service covers several interconnected activities. The first is goods receiving, where incoming shipments are inspected, documented, and logged into inventory systems. This is followed by storage, which may involve palletized racking, bin storage, or climate-controlled zones depending on the nature of the products.

Another key function is inventory management. Warehouses track stock levels, movement, and aging to help businesses avoid overstocking or stockouts. Many facilities also handle order processing, including picking, packing, labeling, and preparing shipments for dispatch. These services are designed to reduce handling time and improve order accuracy.

Types of Warehouse Services

Warehouse services are not one-size-fits-all. Different industries require different setups. General warehousing focuses on bulk storage for standard goods, while bonded warehouses are used for imported goods awaiting customs clearance. Cold storage warehouses support perishable items such as food and pharmaceuticals, maintaining strict temperature controls.

In recent years, fulfillment warehouses have gained importance, especially for e-commerce businesses. These facilities integrate storage with fast order processing and last-mile delivery coordination. There are also on-demand and shared warehouses, which allow smaller businesses to access storage without long-term commitments.

Technology in Modern Warehousing

Technology has become central to how warehouse services operate today. Warehouse Management Systems (WMS) help automate inventory tracking, location mapping, and order workflows. Barcode scanning, RFID tagging, and real-time dashboards improve visibility across operations.

Automation tools such as conveyor systems, sorting machines, and even robotics are increasingly common in high-volume facilities. These technologies reduce manual errors, improve speed, and support scalability during peak demand periods. As a result, warehouses are now viewed as strategic assets rather than cost centers.

Benefits for Businesses

Using a professional warehouse service offers several advantages. Businesses can reduce infrastructure costs by avoiding the need to own or manage storage space. Warehousing also improves supply chain flexibility, allowing companies to scale storage up or down based on demand. Faster order processing, better inventory control, and improved delivery timelines contribute directly to customer satisfaction.

Warehouse Services in Today’s Logistics Ecosystem

In the broader logistics ecosystem, warehouse services act as the backbone that connects suppliers, sellers, and delivery networks. Many logistics aggregators now combine warehousing with transportation and technology platforms to provide end-to-end solutions. Providers like Shipdaak integrate warehousing with shipping, COD support, and e-commerce tools, enabling businesses to manage storage and fulfillment through a single operational flow while maintaining speed and reliability across deliveries.