Foundation-Based Crane Rails Insights and Benefits

Crane rail systems are critical components in our modern industries, from ports and shipyards to manufacturing and mining. One specialized form within this domain is foundation-based crane rails, a solution designed to endure immense loads while delivering exceptional stability, safety, and efficiency.

Foundation-based crane rails aren’t just a support system; they are an engineering marvel that optimizes industrial operations at scale. Let’s explore what makes them indispensable, how they operate, and why global leaders, like Suzhou Xingrail Rail FastenTech Co., Ltd., are at the forefront of providing innovative solutions in this sector.

What Are Foundation-Based Crane Rails?

Foundation-based crane rails are a type of track system that serves as the foundation for heavy equipment like gantry cranes, automated transportation systems, and stacker machines. Unlike standard rails, these are reinforced with a solid, durable foundation, enabling them to withstand high loads, shock, and vibrations.

Such systems are often employed in environments that demand precision and safety, like ports for container movement, mining sites, and steel production factories. Their unique ability to maintain alignment and reduce structural stress has made them a favorite in industries requiring heavy-duty lifting and movement.

Why Foundation-Based Crane Rails Are Essential

Durability and Stability

The added reinforcement from a specially designed foundation ensures these rails can handle massive loads without deformation. This increases the system’s lifespan and minimizes the need for frequent maintenance, reducing downtime significantly.

Precision Performance

High-precision engineering in foundation-based crane rails enables exact alignment and smooth operation. The stability offered by these systems is crucial when complex machinery, like gantries and trolleys, requires seamless mobility.

Enhanced Safety

Safety is a top priority in industrial operations. These rail systems are designed to keep cranes and heavy machinery securely on track, reducing the risk of accidents due to derailments or instability.

Adaptability Across Industries

From ports and shipping yards to mining and warehousing, foundation-based crane rails cater to various applications. They are versatile solutions tailored to meet the unique demands of different sectors.

The Role of Suzhou Xingrail Rail FastenTech Co., Ltd.

When it comes to advanced solutions in rail fastening, Suzhou Xingrail Rail FastenTech Co., Ltd. stands out as a global leader. Leveraging more than nine years of experience and a commitment to excellence, Xingrail has carved a niche for itself in the rail fastening industry.

Key Offerings

- Rail Fastening Systems: Designed for durability and reliability to handle heavy-duty industrial applications.

- Turnout Systems: Engineered for smooth switching between rail tracks in transport and logistics setups.

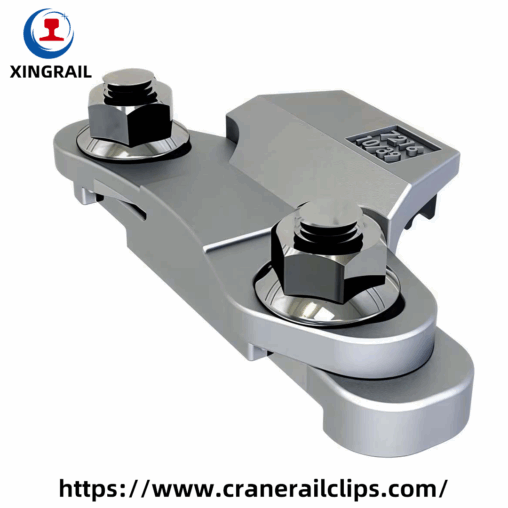

- Crane Rail Clamps and Clips: A range of options, including self-locking and welded rail clips, ensuring stability and ease of installation.

Markets Served:

Xingrail provides solutions to industries such as:

-

Ports and Shipping

Container bridges and shipbuilding gantry cranes rely on XGRS flexible rail fixing systems for streamlined operations.

-

Mining

From crushed stone yards to coal transfer tracks, Xingrail’s solutions deliver maximum efficiency.

-

Automated Warehousing

Rail systems designed with high precision to accommodate intelligent robots and reduce mechanical failures.

With operations in 118 countries and 91 product categories, their expertise is unparalleled.

Understanding the XGRS Flexible Rail Fixing System

One of Xingrail’s standout offerings is the XGRS Flexible Rail Fixing System, which is widely lauded for its adaptability and advanced engineering.

Key Applications

-

Heavy Equipment

Perfect for robust settings such as steel manufacturing, coking equipment, and gantry crane operations.

-

Dynamic Rail Operations

Utilized in high-impact applications like cross-sea bridge tracks and heavy freight railroad lines.

-

Aerospace and Warehousing

Essential for high-precision rail tracks supporting industries that demand reliability and accuracy.

Benefits

-

High Durability

Reinforced materials and innovative design extend the life of the rail system.

-

Precision Alignment

Keeps machinery running smoothly, reducing operational disruptions.

-

Reduced Maintenance

Anti-settling design minimizes wear and tear, lowering upkeep frequency and costs.

Industries That Rely on Foundation-Based Crane Rails

Ports and Terminals

Handling bulk cargo, such as coal and grains, in ports requires tracks that can endure the weight and frequency of loading operations. Crane rails installed at docks and container bridges enable efficient loading and unloading, directly impacting productivity.

Railroads and Urban Transit

The precision required in railroads and urban transit projects underscores the importance of rail fastening solutions capable of sustaining high-speed rail and metropolitan transit systems.

Mining

From large bucket-wheel excavators to continuous haulage systems, mining operations need stable, long-lasting crane rail systems that ensure safety and minimize equipment failure.

Warehousing and Automation

Warehouses increasingly rely on automated systems like stacker cranes and robots. These require high-precision crane rail tracks to operate flawlessly, ensuring the smooth movement of goods in and out of storage facilities.

Why Partner with Xingrail?

What sets Xingrail apart? Their commitment to innovation, quality, durability, and customer-first services. The company ensures its rail systems meet global safety standards and deliver unmatched precision, ensuring clients remain ahead of the curve in competitive industries.

Xingrail at a Glance:

- 9 years of fastener production experience

- Operations in 118+ countries and regions

- 91+ product categories

Their TUV/SGS System Certification further underscores their commitment to delivering excellence. Whether you’re building infrastructure at a port or upgrading your automated warehouse, Xingrail provides tailored solutions to meet your specific needs.