The Role of Heavy Transport Rail Tracks in Modern Industries

When it comes to industries that rely on the seamless movement of heavy goods, few infrastructural elements play as critical a role as heavy transport rail tracks. From railways and ports to mining and power generation, these tracks are the backbone of countless operations. But what ensures the stability, efficiency, and longevity of these tracks? The answer lies in precision engineering, robust materials, and expert installation provided by specialized rail fastening systems.

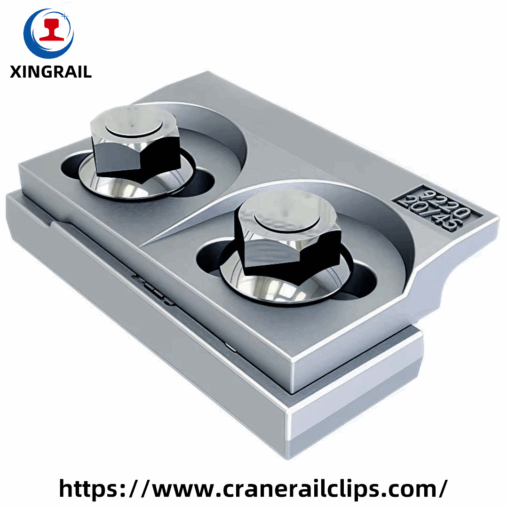

Enter Suzhou Xingrail Rail FastenTech Co., Ltd., a global leader in rail fastening solutions, known for its commitment to innovation, durability, and performance. This article dives into the essential role heavy transport rail tracks play across industries and highlights the innovative solutions offered by Xingrail.

Why Heavy Transport Rail Tracks Matter

Heavy transport rail tracks support industries that rely on the consistent, efficient movement of goods and materials. Here’s why they are indispensable:

- Safety: Tracks designed to support high loads reduce derailments, accidents, and operational hazards.

- Efficiency: Robust rail systems ensure smooth operations, minimizing delays and downtime.

- Durability: High-quality materials and engineering extend the life cycle of tracks, reducing the need for frequent replacements.

- Cost Savings: Effective rail systems optimize operational costs by improving productivity and reducing maintenance expenses.

Each of these benefits is maximized through the use of well-engineered rail fastening systems, ensuring the stability and functionality of heavy transport tracks in various environments.

Industries That Depend on Heavy Transport Rail Tracks

-

Railways

Railways form the foundation of freight and passenger transport. With increasing demand for reliability and safety, rail fastening systems have become pivotal. Heavy-duty fasteners manufactured by Suzhou Xingrail ensure stability, mitigate vibration, and can adapt to extreme conditions across freight lines, urban rail systems, and even ocean-crossing bridges.

Xingrail’s innovative fastening products also meet modern standards for speed and load-bearing capacity, making them a trusted solution for railway infrastructure worldwide.

-

Ports and Shipyards

Ports are critical links in global supply chains, requiring tracks capable of handling massive loads. Xingrail’s XGRS flexible rail fixing systems are widely used in shipbuilding gantry crane tracks, container site bridge tracks, and dock slideway tracks. These fastening systems excel in durability and self-locking mechanisms, keeping operations smooth amidst heavy workloads.

Ports that adopt such advanced systems see fewer disruptions and maintain consistent productivity even in high-pressure environments.

-

Mining and Resource Extraction

The mining industry demands rail systems that can handle harsh conditions and high payloads. Tracks used for crushed stone yards, coal trolleys, and stacker machines function only as well as the fastening systems that hold them together. Here, Xingrail’s anti-settling rail clips and heavy-duty fasteners prove invaluable, ensuring unmatched durability, even in rugged terrains.

With solutions custom-designed for the unique challenges of mining operations, Xingrail enhances safety and operational efficiency in environments where failure is not an option.

-

Power Generation and Heavy Manufacturing

Steel and power plants require precision-made rail systems to move heavy equipment such as overhead cranes and coking machinery safely. The XGRS flexible platen assemblies offered by Xingrail meet the stringent requirements of this sector, delivering solutions that handle complex structures with ease.

Xingrail has carved a niche here, offering rail fasteners designed to reduce vibration wear, ensuring equipment longevity, and optimizing workflows in power and manufacturing facilities.

-

Automated Warehousing

With the rise in automation, rail systems in warehouses have evolved to cater to high-precision equipment like stacker cranes and intelligent robots. Xingrail’s rail fastening systems reduce failure rates and maintain alignment, making them ideal for automated processes where precision is key.

-

Aerospace

Even the aerospace sector relies on heavy transport tracks during the construction and maintenance phases of space equipment. For example, Xingrail’s rail fixing systems are integral to launch platform tracks and dynamic vehicle maintenance depot tracks. Meeting the rigorous standards of aerospace projects, these solutions demonstrate Xingrail’s capacity to deliver reliability at every level.

Suzhou Xingrail Rail FastenTech Company Overview

For industries looking to invest in long-lasting and efficient rail systems, Suzhou Xingrail Rail FastenTech Co., Ltd. is a name that stands out. Specializing in the design, production, installation, and technical servicing of advanced rail fastening systems, Xingrail offers:

- Innovative Designs: Leveraging cutting-edge engineering to create products tailored to specific industrial needs.

- Comprehensive Range: Rail fastening systems, turnout systems, track fasteners, and crane rail clamps to meet diverse demands.

- Global Footprint: Xingrail products are exported to over 120 countries and trusted by companies worldwide.

- Focus on Quality: Certified by TUV/SGS, Xingrail guarantees compliance with international standards, ensuring safety, durability, and performance.

- Versatile Applications: From railways to ports, mining to aerospace, Xingrail products bring value to a wide range of industries.

The Xingrail Difference

What sets Xingrail apart from competitors is its ability to adapt and innovate. Their solutions address not only the functional requirements of rail systems but also consider sustainability, cost-effectiveness, and ease of installation. Key features include:

- Flexible Systems: Accommodates the unique demands of high-load operations across different terrains.

- Eco-Friendly Materials: Designed with a focus on reducing environmental impact without compromising on strength.

- Anti-Settling Mechanisms: Additional stability for heavy-duty applications, ensuring operational reliability.

How Xingrail is Shaping the Future of Rail Systems

As industries continue to demand faster, safer, and more efficient transport systems, Xingrail remains at the forefront of innovation. The company is committed to pushing boundaries, developing next-gen products that cater to emerging challenges like smart automation and sustainability. Through its focus on R&D and customer partnerships, Xingrail ensures lasting value for its clients.

Building Resilient Infrastructure for the Modern World

Heavy transport rail tracks are more than just a means of moving goods; they are an investment in efficiency, reliability, and safety. Whether you operate a port, a manufacturing plant, or a mining facility, implementing advanced rail fastening systems is the first step toward building world-class infrastructure.

With a proven track record and a commitment to excellence, Suzhou Xingrail Rail FastenTech Co., Ltd. is your reliable partner in this endeavor. Their innovative solutions are engineered to withstand the most demanding conditions, delivering superior performance where it matters most.

Discover how Xingrail can elevate your operations by exploring their products and services. Visit their website today to learn more about how their solutions can meet your unique needs.